Knowledgebase

Principle of Measuring

AMI encoders with optical scanning are manufactured with incremental graduations which are applied on to glass and/or etched in phosphorous bronze.

The information of a position is given by counting each increment, starting form a zero-pulse placed at an optical place, forwarded to the signal-operating electronic component. The zero-pulse ist determined by an additionally applied reference-marker.

The graduations applied are mainly manufactured in lithographic processes. This process allows very precise and exact sharply edged graduations. Combined with the photoelectric scanning method and a modern analysis of electronics a high quality of signals can be reached.

Accuracy

Major points in determining accuracy are:

_accuracy in graduation of pulse-disc and scanning board

_accuracy in rotation of bearing of shaft for pulse disc

_centering of pulse disc

_malfunctions/failures arising by connecting the encoder with coupling

In general with encoders a non-accuracy of +/- 1/20 graduation range can be assumed.

Scanning

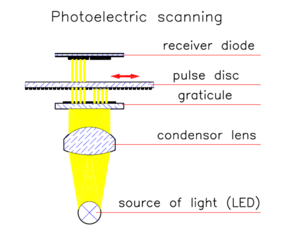

We are working with a photoelectric scanning procedure in our company referring to almost all encoders. Scanning is effected contact free and therefor no wear emerges. Even most precise pulses and or signal-periods are identified. The light of a LED interfuses a scan-board on which there is fixed a grid pattern.

If the on top placed pulse-disc starts to rotate light/dark positions are reproduced. The light-sensitive receiver on the electronic component converts these pulses in nearly sinus-like signals. On adequate preparation on the above both square wave or sinus signals on signal-output are available for the end-user.